Why Conveyor Belts Are Vital in Chocolate Production

In a chocolate factory, precision and efficiency are key to ensuring consistent quality. Conveyor belts streamline production by:

- Optimizing Workflow: Automating the movement of materials, from raw cocoa to packaged products.

- Ensuring Food Safety: Food-grade materials reduce contamination risks.

- Improving Quality Control: Conveyor belts maintain consistent handling, minimizing damage to fragile chocolate pieces.

At Rubberbits and Industrial Conveyors, we specialize in high-performance conveyor systems designed specifically for New Zealand’s chocolate manufacturing needs.

How to Choose the Right Conveyor Belt for Chocolate Production

Selecting the perfect conveyor belt involves considering several factors:

1. Material Composition

- Polyurethane (PU) Belts: Known for their smooth, easy-to-clean surface.

- Silicone-Coated Belts: Great for handling temperature extremes, like cooling chocolate.

2. Compliance with Food Safety Standards

Ensure your belts comply with FDA and EU food safety regulations, guaranteeing safe contact with consumable products.

3. Durability and Features

- Non-Stick Coatings: Prevent chocolate from sticking, keeping the process smooth.

- Temperature Resistance: Essential for stages involving heating or cooling.

- Flexibility: Belts with cleats or custom sidewalls can handle everything from liquid chocolate to boxed goods.

Installing Conveyor Belts in Chocolate Factories

At Rubberbits, our installation process is designed for maximum efficiency and minimal disruption:

- Initial Assessment: We visit your site to understand production flow and challenges.

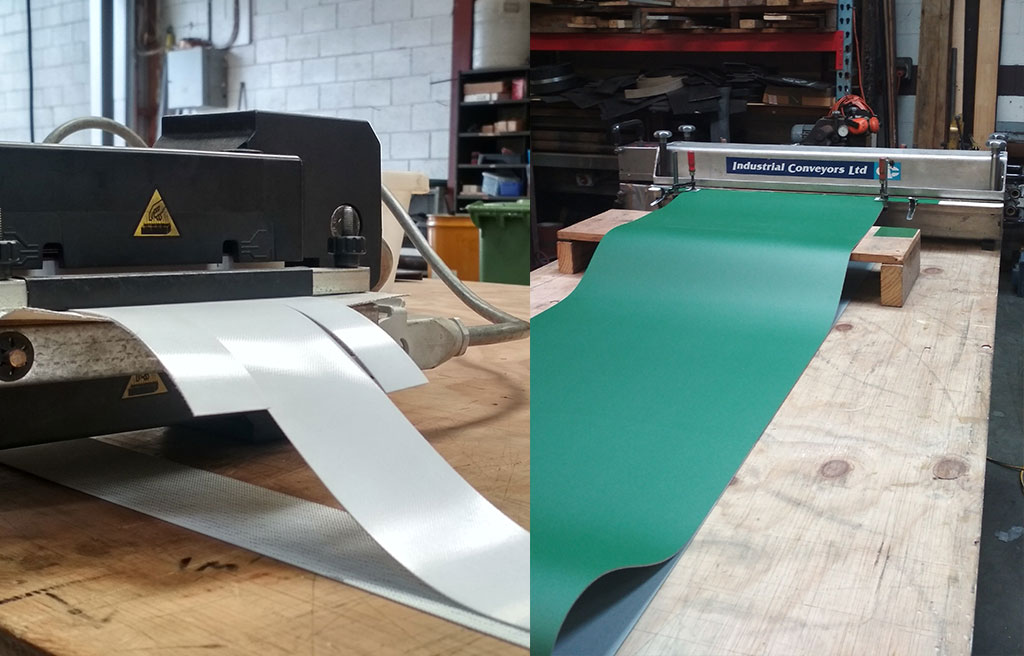

- Customized Solutions: Our team fabricates belts tailored to your factory’s specific needs.

- Professional Installation: Ensuring correct alignment, tension, and smooth integration with your system.

- Post-Installation Testing: Every system is tested to ensure seamless performance from day one.

Maintenance Tips to Extend Conveyor Belt Lifespan

Proper maintenance ensures your conveyor belts run efficiently and last longer:

- Regular Cleaning: Use food-safe solutions to remove chocolate residue.

- Frequent Inspections: Identify wear or misalignment early to avoid costly downtime.

- Quick Repairs: Replace worn parts like cleats or rollers immediately to prevent system failures.

Why Rubberbits Stands Out

Here’s why New Zealand chocolate factories trust Rubberbits:

- Extensive Experience: Over 45 years of expertise in supplying and maintaining conveyor systems.

- Custom Solutions: Every belt is designed to meet your unique production requirements.

- Local Support: With New Zealand-based services, we’re always ready to assist.

Ready to Upgrade Your Conveyor System?

Take your chocolate production to the next level with Rubberbits and Industrial Conveyors. Contact us today to learn how we can help improve your efficiency and reduce operational costs.