BHM01 Surface Friction Tester

Surface Friction Tester is used for the accurate measurement of runway surface friction. It is the special instrument to guarantee the security of plane’s landing and taking off. The vehicle is equipped with water tank and watering system itself, which possesses general applicability and can be applied into concrete surface or pitch covers as well. The constant automatic measure length can be set within 7000 meters and this vehicle is able to work normally despite of rainy or snowy days..

Key features

Ford Taurus(V6 LTD/V6 Flagship), Honda Acura, BYD Tang(EV), Chinese and English menu list, stable -speed cruise, Self-installed water tank, computer control, excellent acceleration, real time print,simple and easy operation, high reliability.

Technical Parameter

| Relative error of friction modulus | ≤ 2% |

| Repeatability error | ≤±0.02 |

| Result standard deviation | ≤0.02 |

| Micro texture testing speed | 96 km/h |

| Macro texture testing speed | 65 km/h |

| Rate of slippage | 15% |

| Tyre type | 4.00-8″ |

| Working temperature | 35 °C ~ +60°C |

| Capability of acceleration | 0~100km/h<6.9s (Ford Taurus |

| 0~100km/h<7.2s (Honda Acura) | |

| 0~100km/h<8.5s (BYD Tang) | |

| Hydraulic system pressure | 6.3Mpa |

| Insulation against ground | 21.5ΜΩ |

| Precision of force sensors | ≤0.02% |

| Tyre pressure | 0.7Mpa |

| Water tank capacity |

580L(Ford Taurus/Honda Acura) 620L(BYD Tang |

Safe design idea

The previous designed proportion for vehicle, such as the frame of car, the appending system, the fuel system and ABS braking system of vehicle chassis have not been converted. It is vital important to guarantee the security, quality and capability of the whole vehicle. What we have done is to reinforce and mount the whole testing system in the concave area within the interior trunk, which enhances the vehicle instead of lessening its structure. The goal of us is to “not only purchase the good car but also use it properly. To diversify the prospective usage of Special vehicle is to gain the dual guarantee from security and benefit.”

Reliability and advantage

We have accumulated the years of designing experience relating the friction modulus testing vehicle, the amount of data relating the airdrome application, and the sensible proposal relating the using departments. It is possible to adjust to the more serious applied working condition, together with the controlled elements for the industrial level’s notebooks which are superior to the identical alien products are all adopted.

All selected parts and materials are the top level. After the most serious examination and testing, this product was widely used in airport,so its reliably and accuracy can be guaranteed.

Acceleration capability

Ford Taurus / Honda Acura /BYD Tang,powerful engine, accelerate quickly, the testing speed can be reached 96 km/h within 200 meters.

Computer control

Use touchscreen keyboard industrial computer with visual menu by adopting the tone mocked operating technique, optimize operating procedure, programming beforehand for continuous detection of the 0~1 friction coefficient value.

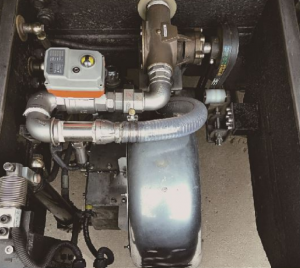

Watering system

Include water tank, pump,presure sensor,valve,pipe fitting and regulationg system. The water tank is made of polypropylene which is the equipped material for the project. The water tank has the capacity of 580-620 litres and can also meet the need of continuous wet testing no less than 7000 meters.

Special tires

Use stripe tires meet the requirements of CAAC, ICAO and FAA, tire material are same as aircraft tires, the working pressure is 0.7 Mpa.

Data acquisition and output

Using the special high speed data acquisition card to data acquisition, test point density reach 3 4 points per meter, improved the data precision. Equipped with the accessory printer to real-time print.